Parachute Folding Machine - Mechanical Design

24 February 2018

The mandate for this class project consists of designing a machine that can quickly and effectively fold parachutes in a reproducible manner. The machine must be able to fold an eight-panel, dome-shaped parachute without any human intervention other than start-up and shut-down. No programmable controllers can be used and a limit of three electric motors is allowed.

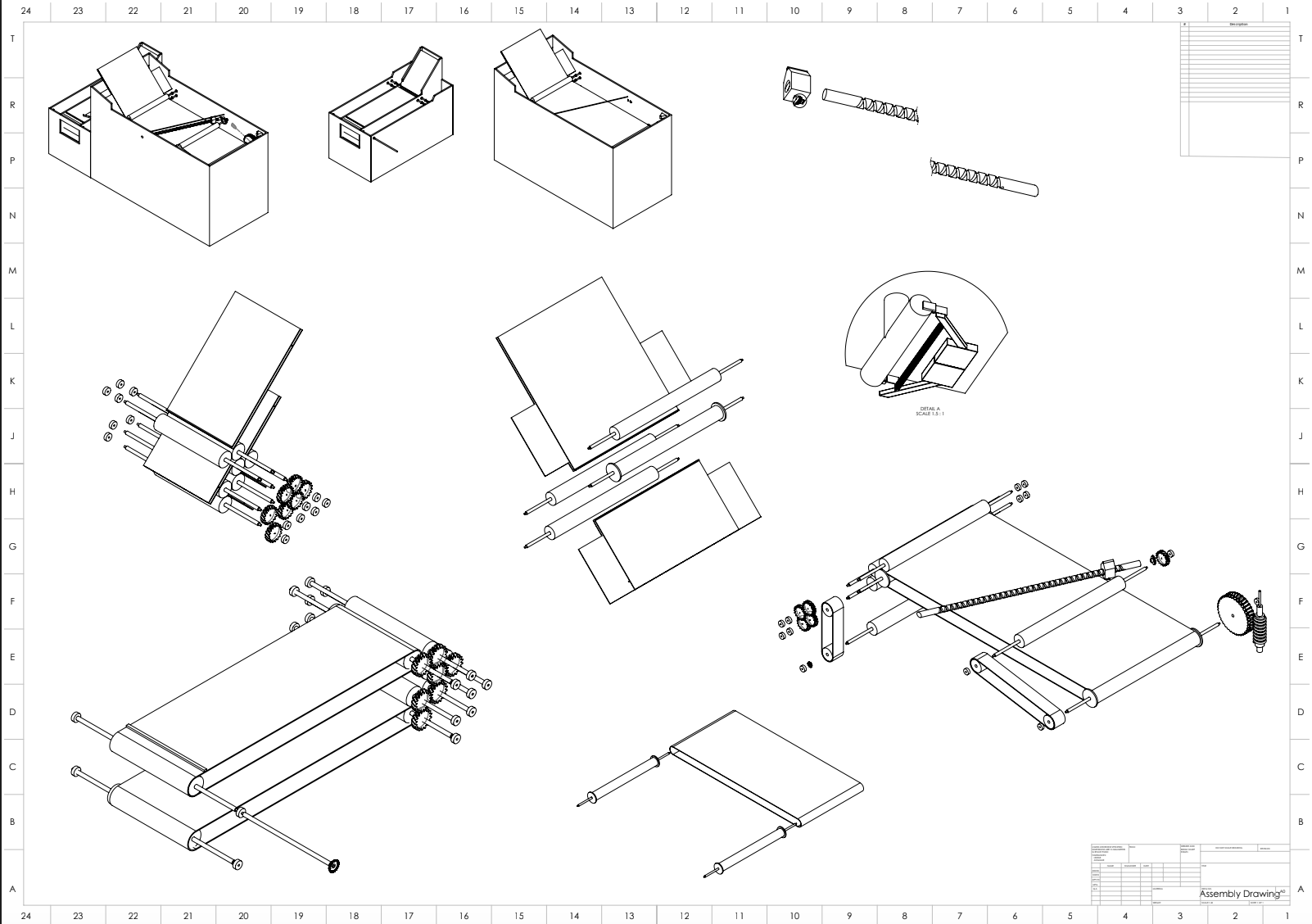

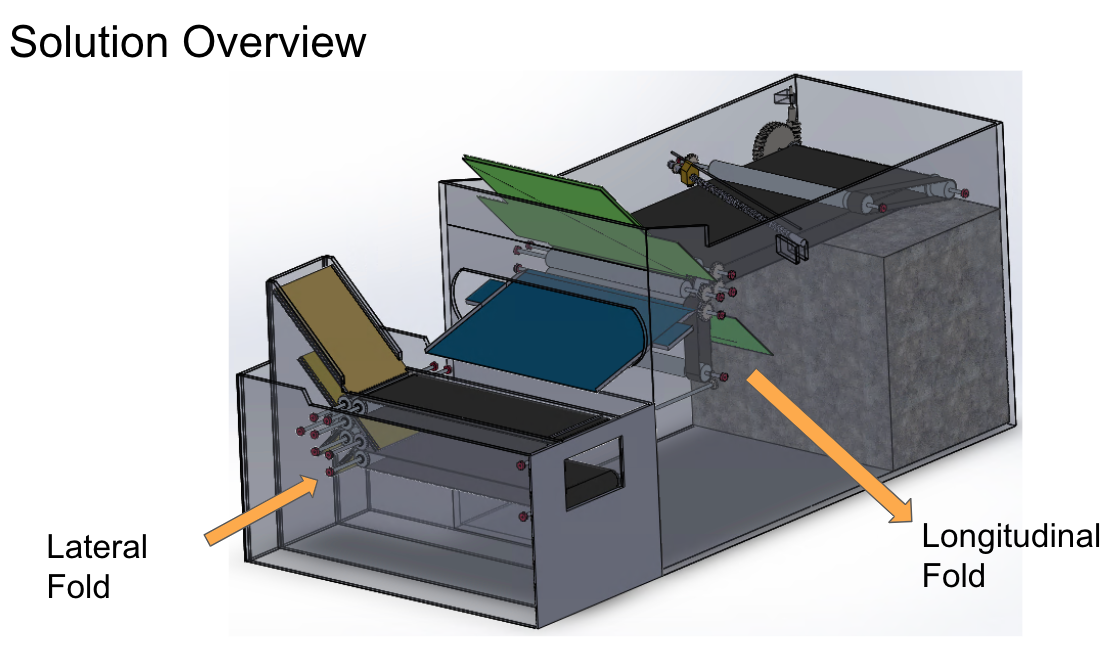

The above figure shows the concept for this machine. It is similar to a photocopy machine which moves paper around using spinning shafts with rollers to push the paper along a predetermined path.

The advantages of this design is that it uses one motor, with a gear transmission that allows for both the lateral and longitudinal folds of the parachute. Using bevel gears the lateral shafts can be engaged with the same motor. Another nice feature of this design is that it doesn’t use complex parts to get the fold sequence correct, it instead, makes use of geometry to get all the folds.

The basic function is that the parachute is pushed along by the rollers, and then hits an end-stop on a flat inclined plate at a certain distance. This distance for the first fold is half the length of the parachute, which means that when the parachute hits the end-stop, the chute will be forced down a second set of shafts and rollers located underneath, which will engage the fold.